Blog

Why Depot Repair and Returns Programs Break at Scale Without API Integration

Why Depot Repair and Returns Programs Break at Scale Without API Integration

Most operations teams accept a version of the same friction when they work with an external depot repair partner: manual status requests, weekly update emails, end-of-month reconciliation spreadsheets, and a customer portal that shows you less than you actually need.

It doesn’t feel like a solvable problem. It feels like the cost of outsourcing. It doesn’t have to be.

The Real Cost of Manual Visibility in Depot Repair Programs

When your depot partner operates as a closed system, your team absorbs the integration burden. Someone becomes responsible for translating between your ERP, CRM, or warranty platform and the depot’s internal software.

That person spends meaningful time, every week, chasing repair status updates, reconciling serialized inventory counts, and fielding internal questions they can’t answer without making a call first.

In practice, this shows up as:

- Inventory discrepancies that take days to resolve because real-time counts aren’t available

- Exception handling that requires back-and-forth emails to locate a unit stalled in process

- Reporting to leadership or upstream customers that cannot be automated because the data isn’t structured

- RMA and order entry that requires a portal login or phone call, neither of which integrates cleanly into your workflow

The cost isn’t visible on a single invoice. It’s distributed across headcount time, process latency, and decisions made on stale data.

What Most Depot Repair Partners Actually Offer

The standard offering from many electronics repair depots is a web portal. You log in, look up units, and export a report if the format happens to work for you.

A portal is useful for occasional manual lookups. It doesn’t help when you need to:

- Surface depot repair status inside your own systems

- Trigger downstream workflows based on repair completion

- Automate warranty claims

- Provide real-time RMA visibility to customers

- Synchronize serialized asset data

The gap between a portal and actual system integration is significant. Most operations teams live in that gap without a clear path out of it.

What Integration Should Actually Look Like

When a depot partner is built to integrate, the conversation shifts. Instead of asking, “Can you send us a status report?” you’re asking, “What endpoints do you expose?”

A production-ready depot repair integration should support:

Real-Time Status Queries

Your systems can query repair or refurbishment status instantly by serial number, RMA, or order ID, without logging into a portal.

Inventory Visibility

Live inventory data by SKU, condition, or location. Month-end reconciliation becomes a comparison of structured datasets, not an investigation.

Programmatic RMA and Order Entry

New RMAs and staging orders can be created directly from your ERP, CRM, or warranty system via API. No duplicate entry. No transcription risk.

Trigger-Based Workflows

Repair completion can trigger automated actions on your side, credit issuance, replacement shipment, customer notification, or analytics logging.

Custom Data Endpoints

Real-world programs have edge cases. Integration should allow for scoped, structured endpoints that map cleanly to your internal data model.

Microland’s Service API

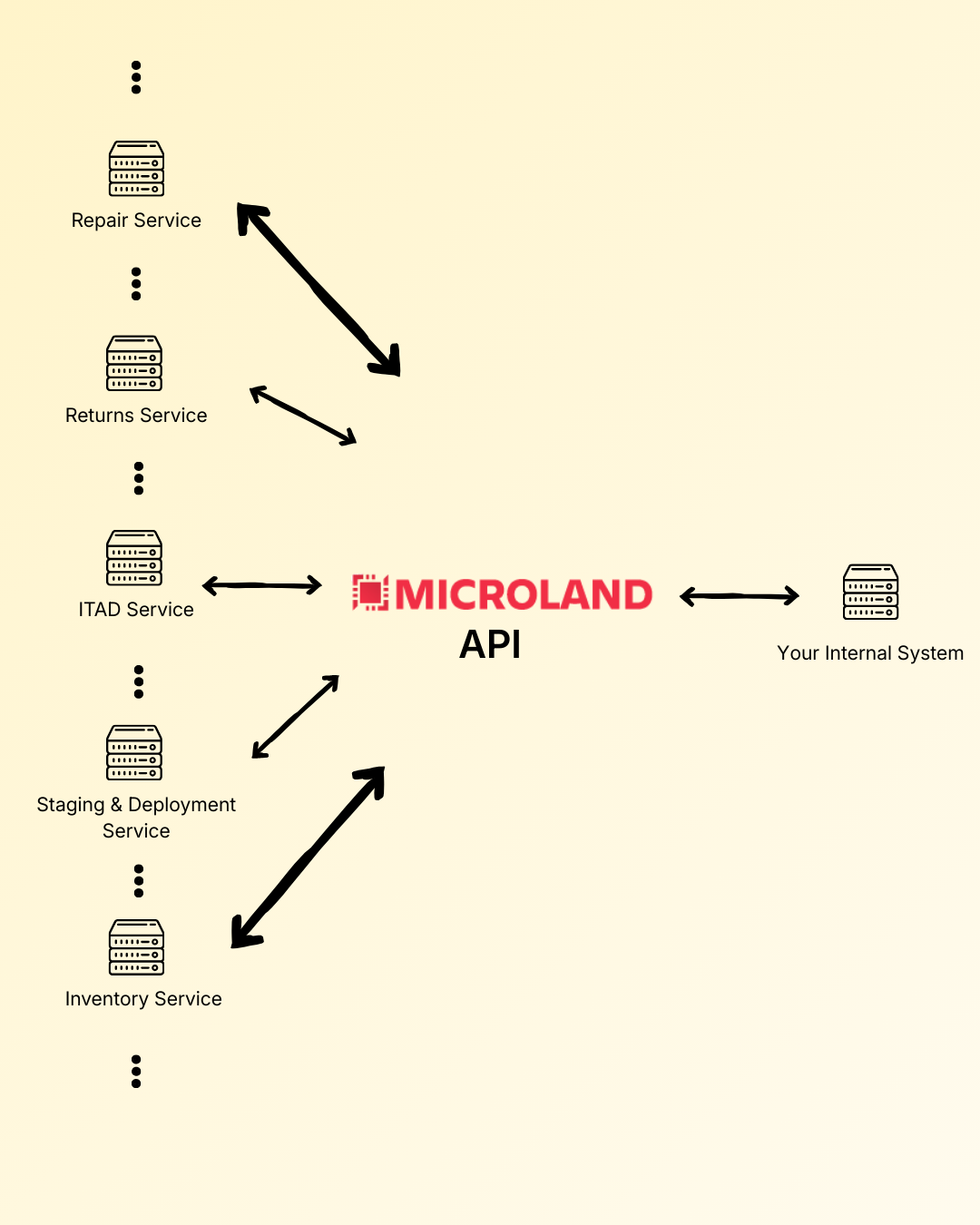

Microland provides a production-grade service API that supports:

- Real-time RMA status integration

- Serialized repair tracking

- Inventory position queries

- Programmatic RMA and order submission

- Structured JSON data exchange

- Custom integration endpoints

For organizations with existing integration infrastructure, we can connect directly to your systems.

For organizations that expose their own API layer, Microland can integrate outward, consuming or synchronizing with your API architecture to ensure bi-directional data flow.

In practical terms, this means integration can be structured around your preferred system of record, not ours.

Why Most Depot Partners Don’t Offer This

Building and maintaining a true API integration layer requires dedicated software investment, structured data architecture, and ongoing version support.

Historically, repair depots competed primarily on:

- Cost per unit

- Turnaround time

System integration wasn’t considered a differentiator because customers had accepted manual reporting as standard.

That ceiling becomes obvious at scale.

OEMs managing high-volume warranty programs, distributors processing large return flows, and IT lifecycle managers tracking serialized assets quickly discover that spreadsheet-based depot relationships don’t scale with program growth.

Integration stops being a “nice to have.” It becomes operational infrastructure.

What to Ask When Evaluating a Depot Repair Partner

If you’re assessing depot partners, especially for an OEM warranty, reverse logistics, or refurbishment program, integration capability is worth pressure-testing early.

Questions worth asking:

- Do you provide API access for repair status and inventory queries?

- Can RMAs and staging orders be submitted programmatically?

- How do you handle versioning and API updates?

- Can you integrate with our API architecture if we expose endpoints?

- What does implementation and ongoing support look like?

A partner that can answer these clearly operates very differently from one that defaults to “we have a portal.”

Service Integration as Scalable Infrastructure

The spreadsheet-and-email model does not scale with growing RMA throughput, refurbishment programs, or serialized fleet management.

Microland’s integration layer exists because the manual alternative had measurable operational cost, even when that cost wasn’t immediately visible.

Most depot relationships break at scale. If your program is growing, it’s worth evaluating whether your integration layer will grow with it.

Are you looking to establish a respected service presence in Canada? Contact Us for more info